Description

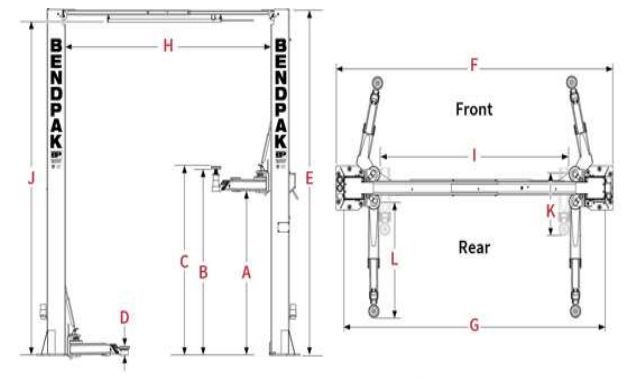

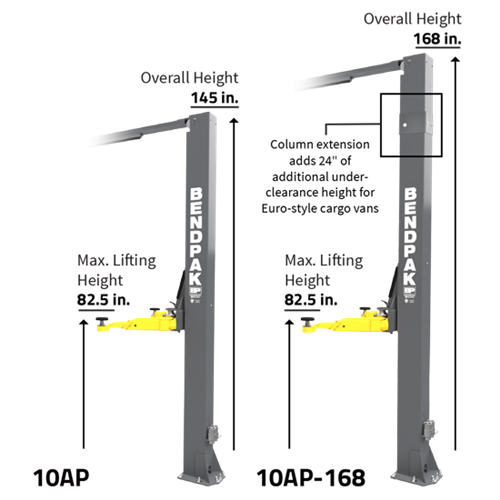

10AP This is our standard model that features 73" of lifting height and an overhead beam height of just 145" for shops with lower ceiling clearances.

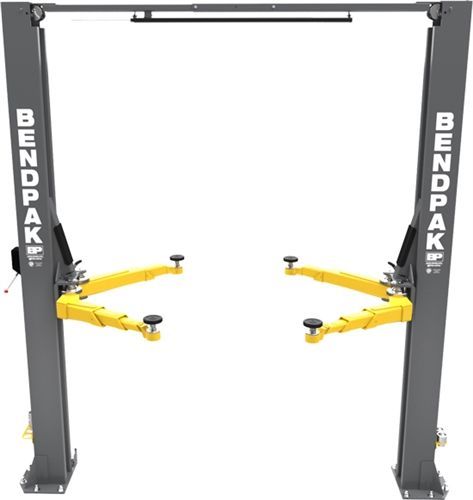

BendPak 10AP Adaptable Clearfloor ALI 2 Post Car Lift 10,000 lb. Capacity

• Clear-floor convenience – unobstructed floor space allows technicians the ability to

easily move toolboxes, transmission jacks, oil drains, and other equipment

underneath elevated vehicles.

• Bi-MetricTM swing arms – give users the ability to set their lift up in either

symmetric or asymmetric configurations. The 2-in-1 design gives installers and

operators the option of loading vehicles either symmetrically (centerline of vehicle at

column) or asymmetrically (centerline of vehicle behind column).

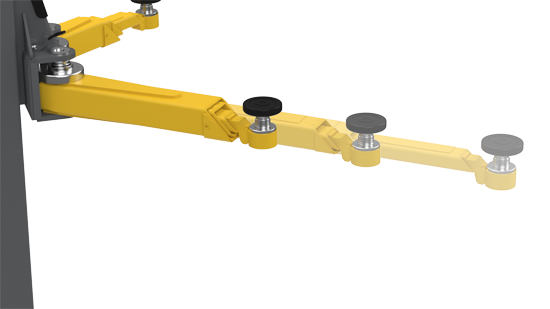

• Low-Pro™ swing arms – low-profile telescoping swing arms offer less hindrance

providing increased versatility and less chance of damage to vehicle side skirts,

running boards, or ground effects.

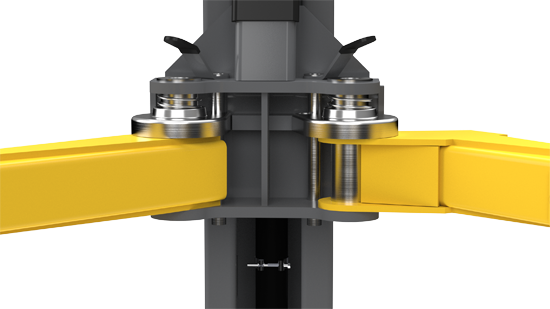

• Automatic arm restraints – each arm is equipped with durable 360-degree full

contact geared arm restraints that provide over 2000-pounds of load-holding force

and automatically engage each time the lift is raised. When the lift is lowered, the

gear- type arm restraints automatically disengage to provide easy positioning of the

lift arms.

• Configurable wide or narrow installation – allows you to maximize the use of your

floor space.

• Single-piece columns – we purposely manufacture the columns using single-piece

construction for added strength and less fatigue under heavy load conditions.

• Maintenance free load bearings – rather than using roller bearings that need

constant lubrication and maintenance, every AP series lift carriage uses futuristic

ultra-high molecular weight (UHMW) polyethylene load bearings that never need

lubrication and last virtually the life of the lift.

• Dual Direct-Drive technology – by utilizing two low-pressure Direct-Drive cylinders,

we’ve eliminated the need for lifting chains or screw mechanisms most commonly

found on other lift designs. This Direct-Drive technology offers better reliability,

smoother operation, and less maintenance. Low pressure means a much smaller

workload is placed on the entire hydraulic system.

• Single-point safety release – the single-point safety release and dead-man style

operation controls makes every one of our AP series lifts easy to operate and safe to

use.

• On the level – our Dual-Synchro equalization system maintains equal lifting and

provides operators with a stable, level vehicle working condition.

• HVLP hydraulic system – every AP Series lift uses a High Volume Low Pressure

(HVLP) electric-hydraulic power system that delivers high fluid volume while

maintaining low system pressure. Because the hydraulics are not constantly under

high pressure, seal failure and leakages are much less likely to occur.

• Industrial-grade hydraulic cylinders – integrated into every AP Series hydraulic

cylinder is a one-piece, pilot-fitted, machined-steel piston wrapped with specially

designed, pressure-loaded U-cup piston seals, backups, and wear bands that

virtually eliminate any fluid bypass. A micro-smooth chrome rod is machined from

high-yield, ground and polished alloy steel and the welded cylinder body exceeds

ASTM specifications.

• Super-tall lift carriages – 53" & 59" tall carriages are considerably taller than most

two-post styles, which minimizes the stress placed on the load bearings and

columns.

• Varying height stackable adapters – a 14 piece (12 adapters + 2 racks) set is

included as standard accessories providing greater vertical pad placement for precise

and safe vehicle support